Outdoor Textiles: Resistance to UV - Weathering Exposure Testing

- Thursday, 14 March 2024

The most common tests for outdoor fabrics is to look at weathering and its effects on the product durability.

For example: Appearance - colour, cracking and peeling.

Part 1: Resistance to UV - Weathering Exposure Testing

Artificial weathering involves exposing test specimens to an artificial UV light source in a cabinet in which the temperature, humidity and water spray are controlled. The key parameter in all accelerated weathering apparatus is the UV light source, which should ideally simulate solar radiation.

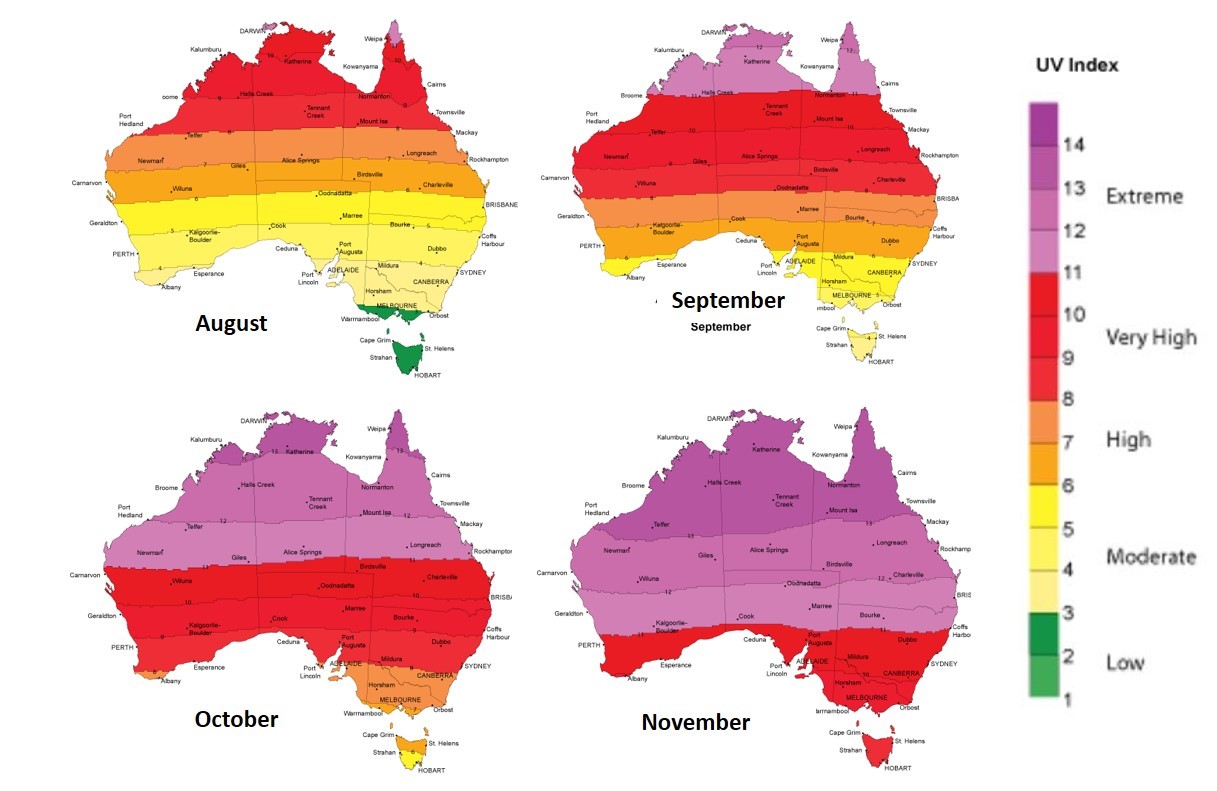

It is important to note that there is no “foolproof” test that will provide an accurate prediction of service performance and life expectancy or that will accommodate the wide range of climatic conditions experienced geographically. As can be seen in the image below, just in Australia alone the UV levels vary between states and throughout the year.

Image Source: Commonwealth of Australia, BOM - 2012

Artificial light sources used in Australia for UV resistance assessment are the Xenon-arc lamp combined with a number of different filters to simulate various exposure conditions (e.g.: ISO 4892.2, AATCC TM169, ASTM G155) and Fluorescent tube - UVA & UVB (ISO 4892.3, ASTM G154).

How can we help you?

AWTA Product Testing can provide UV exposure testing with both the Weatherometer, using a Xenon-Arc lamp or the QUV tester, using UV-A or UV-B lamps. Detailed information on these exposures, including some typically requested cycles from the ASTM methods follow.

Technologists are available to discuss these options, as well as other national and international standard methods with you, and can provide a detailed quotation for your preferred options.

The test exposure fees quoted include access to the entire machine for the exposure period. Test specimens can be removed from the apparatus to conduct performance tests or appearance assessment as required during this time. Appearance assessment may include such processes such as colour change, gloss change and cracking/peeling / texture changes. A separate fee may be charged for these types of assessments.

UV exposure using Weatherometer tester (Xenon Arc light source)

The Weatherometer accommodates up to 48 specimens (75mm x 150mm). A reduced number of larger specimens can also be exposed. Specimens are exposed to repetitive cycles of light and moisture under controlled environmental conditions. Moisture is usually produced by condensation of water vapour onto the test specimen or by spraying the specimens with demineralized/deionized water.

The exposure condition may be varied by selection of:

- The filters used on the Xenon lamp,

- The lamp’s irradiance level,

- The type of moisture exposure,

- The timing of the light and moisture exposure,

- The temperature of light exposure, and

- The temperature of moisture exposure, and

- The timing of a light/dark cycle.

Some commonly used exposure conditions for simulating weathering are listed below. (These examples have been taken from Table X3, ASTM G155).

|

Cycle |

Filter |

Irradiance |

Wavelength |

Exposure cycle |

|

1 |

Daylight |

0.25 W/m2.nm |

340 nm |

102 min light, 63°Cblack panel temperature 18 min light and water spray |

|

6 |

Window glass |

1.10 W/m2.nm |

420 nm |

3.8hr light, 35% RH, 63°C black panel temperature 1.0 dark, 90% RH, at 43°C black panel temperature |

|

7 |

Extended UV |

0.55 W/m2.nm |

340 nm |

40 min light, 50% RH, 70°C Black panel temperature 20 min light, water spray on specimen face 60 min light, 50% RH, 70°C Black panel temperature 60 min dark, 95% RH, water spray on face and back of specimen |

Table 1: Source - ASTM International (Link: https://www.astm.org/g0155-21.html)

UV light exposure using QUV tester (UVA or UVB light source)

The QUV tester accommodates up to 48 specimens (75mm x 150mm). A reduced number of larger specimens can also be exposed.

Specimens are exposed to repetitive cycles of light and moisture under controlled environmental conditions.

Moisture is usually produced by condensation of water vapour onto the test specimen or by spraying the specimens with demineralized/deionized water.

The exposure condition may be varied by selection of:

- The fluorescent lamp used,

- The lamp’s irradiance level,

- The type of moisture exposure,

- The timing of the light and moisture exposure,

- The temperature of light exposure,

- The temperature of moisture exposure; and

- The timing of any light/dark cycle.

Spectral Irradiance:

NOTE 1 - Fluorescent UVA lamps are available with a choice of spectral power distributions that vary significantly. The more common may be identified as UVA-340 and UVA-351. These numbers represent the characteristic nominal wavelength (in nm) of peak emission for each of these lamp types. The actual peak emissions are at 343 and 350 nm, respectively.

Spectral Irradiance of UVA-340 Lamps for Daylight UV:

NOTE 2 - The main application for UVA-340 lamps is for simulation of the short and middle UV wavelength region of daylight.

Spectral Irradiance of UVA-351 Lamps for Daylight UV behind Window Glass:

NOTE 3 - The main application for UVA-351 lamps is for simulation of the short and middle UV wavelength region of daylight which has been filtered through window glass.

Spectral Irradiance of UVB-313 Lamps:

NOTE 4 - Fluorescent UVB lamps have the spectral distribution of radiation peaking near the 313-nm mercury line. They emit significant amounts of radiation below 300 nm, the nominal cut on wavelength of global solar radiation that may result in aging processes not occurring outdoors.

These lamps may not reflect actual weathering in use, however they can provide comparative data between samples.

Some commonly used exposure conditions for simulating weathering are listed below. (These examples have been taken from Table X2.1, ASTM G154).

|

Cycle |

Filter |

Irradiance |

Wavelength |

Exposure cycle |

|

1 |

UVA-340 |

0.89 W/m2.nm |

340 nm |

8 hours UV, 60°C Black panel temperature 4 hours condensation, 50°C Black Panel Temperature |

|

3 |

UVB-313 |

0.49 W/m2.nm |

310 nm |

8 hours UV, 70°C Black panel temperature 4 hours condensation, 50°C Black Panel Temperature |

|

7 |

UVA-340 |

1.55 W/m2.nm |

340 nm |

8 hours UV, 70°C Black panel temperature 0.25 hours dark, water spray 3.75 hours condensation, 50°C Black Panel Temperature |

Table 2: Source - ASTM International (Link: https://www.astm.org/g0154-23.html)

LINK to Information Sheet: Part 1: Resistance to UV - Weathering Exposure Testing

Contact us:

If you would like further information on Resistance to UV - Weathering Exposure Testing or our testing services in general - please contact us as per below:

Phone: +61 (03) 9371 2400 OR Email:[email protected]